Sustainability

With love to your family and our planet …

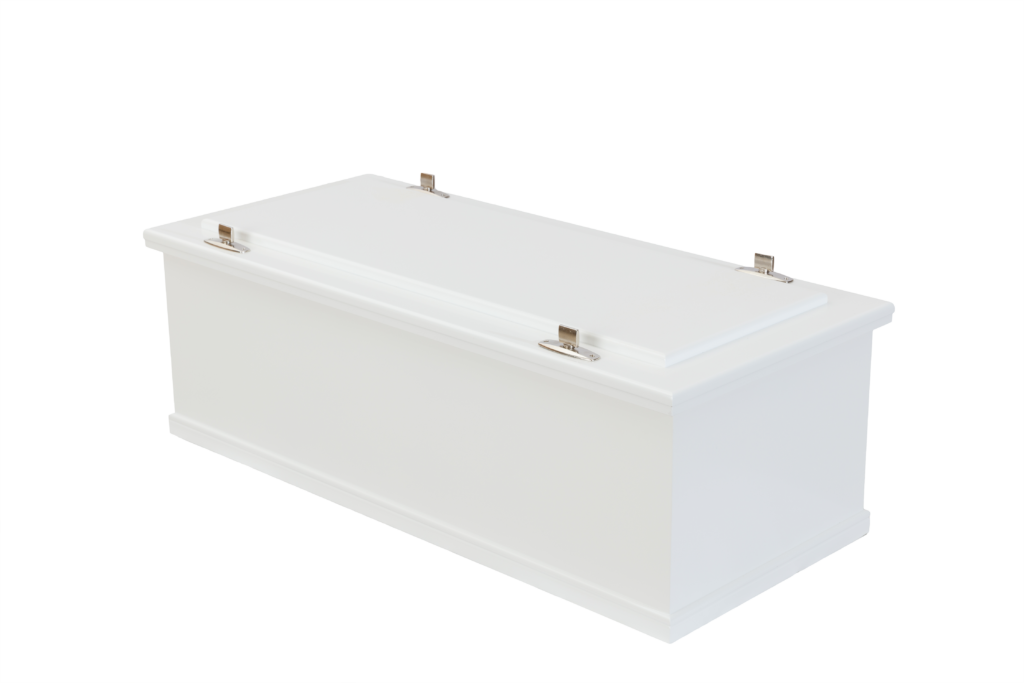

Buying a casket for you or your loved one can be a very emotional experience. Everyone has a story and saying our final goodbyes with a vessel as beautiful as the life lived is a wonderful way to honour that.

At Windsor Indsutries, we strive to make the process of buying a casket just a little less hard, by caring for both New Zealand families and the beautiful environment in our work.

What we are doing…

Eco Choice Aotearoa Accredited

Our Waterford pine caskets are the first and only casket range in New Zealand to be accredited by Eco Choice Aotearoa.

This means we:

- work with NZ Forest Managers to source our pine: NZ Forest Managers have Forest Stewardship Council certification covering 57,000ha of planted forest, and thorough water, pest control and NZ Falcon monitoring systems in place

- use non-toxic, water-soluble glues, water-based stains and sealers.

- reduce waste everywhere we can; programming our cutting machines to make the best use of our wood materials, and even encouraging staff to take home offcuts to use on their craft projects

- integrate power-saving practises into everyday life

- upskilled our staff in Health & Safety, and received our Health & Safety at Work (Hazardous Substances) Location Compliance Certificated from Enviro Haz

The veneer we use on the caskets already carried an Eco Choice label; bonus!

Offcuts of natural timber are cut up and donated to be used for home crafts

Volunteers planting trees donated by Windsor at the Te Tahawai Wairoa Stream Restoration Project

Trees That Count

For every solid timber casket purchased, we donate a native tree to be planted in a reserve as a living memorial with Trees That Count.

We provide a certificate for the families. We also have the facility to set up individual memorial tree registries with Trees that Count. This ensures we are helping to provide a better place for coming generations to live in.

Since 2020…

Re-naturing Katikati Taiao

200 trees funded

Manurere Organics Restoration Planting Project

200 trees funded

Awahuri Forest Kitchener Park Trust

200 trees funded

STDC Community Plantings

200 trees funded

Te Mata Park

100 trees funded

Black Pond Farm

150 trees funded

Caskets for

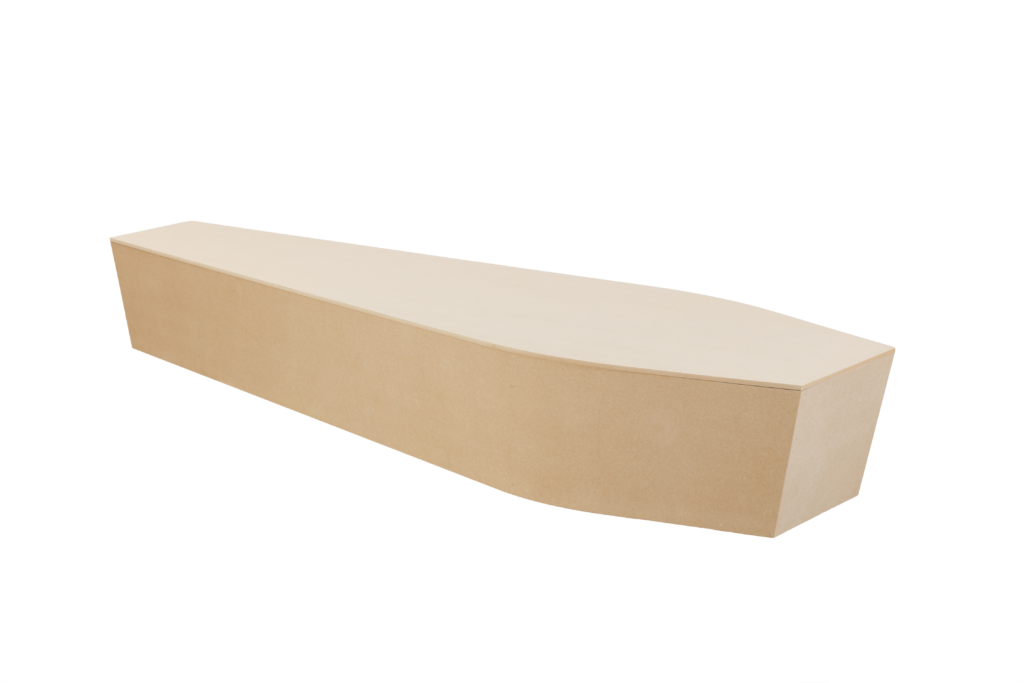

Natural Burials

A natural burial returns the body to the earth in nature’s own way.

- Plots are shallow

- The body is dressed in natural fibres and not embalmed

- The casket is made of untreated, sustainable wood

- The plot is over-planted with a tree native to the area, and the whole cemetery is gradually restored to native bush.

- The cemetery becomes a permanent bush park – a living memorial to those buried there, a home for native flora and fauna, and a beautiful place for family and friends to visit.

Both our Waterford & Dorset casket ranges are suitable for natural burials.

Learn more at naturalburials.co.nz.

Waste Reduction

Briquette Production

The briquette maker and a full load of briquettes, ready to be packaged for sale.